Carbon Injection Dispenser

Price 2100000 INR/ Set

Carbon Injection Dispenser Specification

- Feature

- Corrosion Resistant, High Precision Dosing, Digital Control Panel

- Rating

- IP55

- Condition

- New

- Type

- Automatic Dispenser

- Usage

- Industrial Carbon Injection

- Power

- 3 kW

- Voltage

- 415 V, 3 Phase

- Size

- Customizable as per requirement

- Dimensions

- 1200 mm x 800 mm x 1700 mm (L x W x H)

- Weight

- Approx. 550 kg

- Application

- Steel Plants, Foundries

- Fuel Type

- Electric

- Capacity

- 50-200 kg/hr

- Material of Construction

- Mild Steel with Powder Coating

- Control System

- PLC Controlled with HMI Interface

- Hopper Capacity

- 100 L

- Connectivity

- RS485/Modbus Compatible

- Safety Features

- Overload Protection, Emergency Stop

- Discharge Pressure

- up to 10 bar

- Flexibility

- Adjustable Injection Rate

- Mounting Type

- Skid Mounted

- Display

- Digital Display for Rate and Totalization

- Operating Temperature Range

- 0°C to 55°C

- Maintenance

- Low Maintenance Design

Carbon Injection Dispenser Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10 Sets Per Day

- Delivery Time

- 3 Days

About Carbon Injection Dispenser

I am offering a carbon injection system that has been designed to meet the demanding requirements of the EAF process for the improvement of metallurgical process. The system uses closed loop control with real-time carbon flow rate feedback to provide the exact carbon flowrate that is requested at any time. The use of dispenser, with precise flow-rate control for each injector, allows an efficient injection of carbon fines generates chemical energy by the combustion of C to CO in the liquid bath, and retain it in the slag/steel.The foamed slag that transfers and distributes the chemical energy generated over the entire liquid steel surface. The capacity of the carbon injection system shall be able to sustain with the flow rates and quantities requirements of one carbon lance during at least an entire heat. Consequently we propose the supply of dispensers with 1500 liters capacity. The powder fines could be stored into storage silos. The dispenser should be installed as close as possible to the EAF, in the event that is not feasible, and it is necessary to move away from the furnace area, the maximum linear distance should not exceed 80 meters.

The process of filling the powder fines is automatically controlled by pneumatic on /off fail safe valves and level limit switch.The fines enter to the conveying pipeline, from the dispenser lower exits and transfer the mixture of fines and compressed air to the carbon lance.

Product details

| Usage | Steel Industry |

| Installation Service | Yes |

| Design Type | Customized |

| Injectable Form | Solution |

| Grade Standard | Industrial |

| Material | Cast Iron |

Our Carbon Injector Systems runs trouble free operation with good quality and proper sizing of the powder fines. The equipments shall be equipped with Moisture removing system of the fine to remove the moist from the air that cause problem in maintenance with solenoids and valves and clogging of injection lines.

Precision Dosing with Digital Control

Experience superior accuracy in carbon injection with a PLC-controlled digital dispenser. Our system ensures high-precision dosing tailored to your specific processing needs, making it ideal for steel manufacturing and foundry applications. The integrated HMI interface and digital readouts deliver real-time monitoring and effortless operation.

Robust and Flexible Industrial Performance

Designed with mild steel and powder coating, this dispenser offers durability and corrosion resistance even in rigorous environments. Adjustable injection rates, a wide operating temperature range, and discharge pressure support up to 10 bar ensure high adaptability for various operational requirements.

Engineered for Safety and Connectivity

Safety is paramountthis dispenser features overload protection and an emergency stop to prevent unexpected incidents. Advanced RS485/Modbus connectivity facilitates seamless integration with existing automation systems, enhancing control and reporting for optimized workflow.

FAQs of Carbon Injection Dispenser:

Q: How does the Carbon Injection Dispenser ensure accurate dosing during operations?

A: The dispenser utilizes a PLC-controlled system paired with a digital display and HMI interface, allowing precise adjustment and monitoring of the injection rate. High-precision mechanisms and real-time feedback ensure consistently accurate carbon delivery throughout each process.Q: What settings can be customized in the Carbon Injection Dispenser to meet specific operational requirements?

A: Operators can adjust the carbon injection rate, set up process parameters through the PLC and HMI panel, and customize the dispensers physical dimensions and hopper capacity upon request, ensuring optimal integration into existing plant setups.Q: When should regular maintenance be performed on this dispenser?

A: Thanks to its low-maintenance design, routine checks should be conducted in accordance with the manufacturers guidelines, typically before each production cycle and during scheduled plant maintenance. Key areas to monitor include hopper cleanliness, PLC functionality, and safety features.Q: What is the installation process for this skid-mounted Carbon Injection Dispenser?

A: The skid-mounted design simplifies installation: the dispenser can be positioned at the required location in your plant, followed by straightforward electrical connections (415 V, 3-phase) and system integration using the provided RS485/Modbus interface.Q: Where is this automatic carbon dispenser particularly beneficial?

A: Optimized for industrial carbon injection, the dispenser is best suited for steel plants, foundries, and similar high-demand environments requiring precise, automated dosing and real-time monitoring.Q: How does the system enhance operational safety during use?

A: Equipped with overload protection and an emergency stop function, the dispenser ensures safe shutdown in the event of abnormal conditions. Its IP55 rating provides additional protection against dust and water ingress, further enhancing workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

Premium Quality Carbon Injector System for Electric Arc Furnace

Price 1800000 INR / Set

Minimum Order Quantity : 1 Set

Size : Customizable as per EAF requirements

Usage : Other, For carbon injection in Electric Arc Furnaces (EAF)

Condition : New

Type : Automatic Carbon Injector System

Furnace Cover Lifting Car Electric Arc Furnace

Price 3200000 INR / Set

Minimum Order Quantity : 1 Set

Size : Customizable as per furnace requirements

Usage : Other, Arc Furnace Cover Handling

Condition : New

Type : Furnace Cover Lifting Car

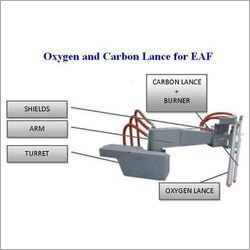

Oxygen & Carbon Lance for EAF

Price 1600000 INR / Set

Minimum Order Quantity : 1 Set

Size : Customizable as per EAF requirements

Usage : Other, For Electric Arc Furnace (EAF) operation

Condition : New

Type : Oxygen & Carbon Lance

Lance Manipulator Revolving Turret for EAF

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Different Size Available

Usage : Other

Condition : New

Type : Lance Manipulator Revolving Turret for EAF

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free