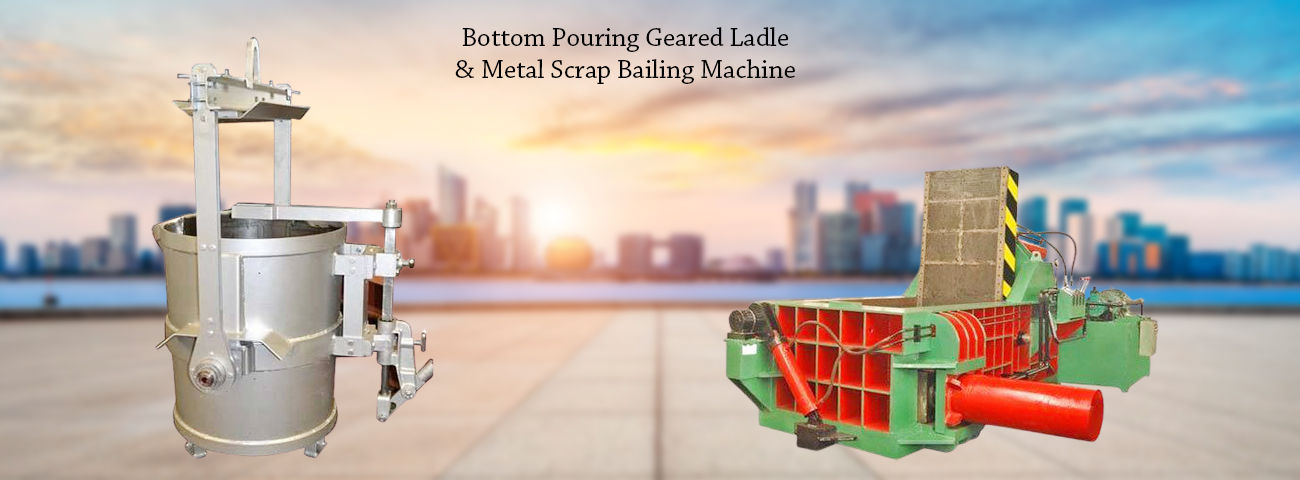

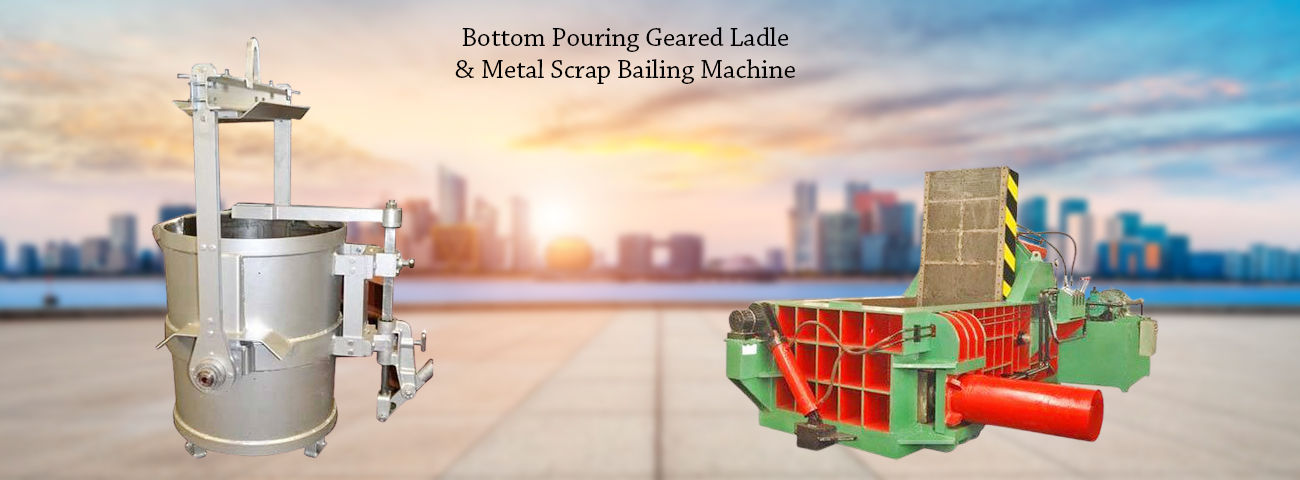

Avail the best solutions including Vacuum Oxygen Refining Tank, Continuous Casting Machine, De Slagging Machine, etc.

Best Seller

Best Seller

About Us

Based on wide experience, we, Remso Control Technologies Private Limited have attained specialization in the offering of a variety of products and services as a manufacturer, supplier, exporter and service provider. Since our establishment in 2001, we have been producing top-quality goods like Tundish Tilter for Bloom Caster, Aluminum And Casi Wire Feeding System, Sampling and Temperature Manipulators, Continuous Casting Machine, Vacuum Oxygen Refining Furnace, etc. In order to produce goods as per international standard and criteria, we have set up an innovative infrastructural facility that is well fitted with high tech equipment and machines. Moreover, Madan Kumar and Manisha Prasad are the Directors of our company who continuously guide us to lead in the market. We are an accredited member of Federation of Indian Chambers of Commerce & Industry, Member of Engineering Export Promotion Council, and Confederation of Indian Industry.

Our Aim

In order to represent our clients more efficiently, we need to have an intuitive understanding of the technologies and dynamics of the market. Our aim is to work collectively and find the right ideas, conveniently and effectively.

Quality Management & Our Team

The main reason behind our success is outstanding quality in every company process and for ensuring this, we have appointed a team of highly trained experts. They have versatile experience in their receptive disciplines which they use to render the finest quality of goods including Sampling and Temperature Manipulators, Vacuum Oxygen Refining Furnace, Tundish Tilter for Bloom Caster, Continuous Casting Machine, etc.

Our Services

Given are the services offered by us:

- Design Engineering and Technical Support

- Projects Management & Contracting

- Manufacturing and Supply

- Project Consultancy

- Erection & Commissioning

- Inspection and Testing

- Trouble Shooting

- Upgradation and Revamping of Steel Melt Shop

- Training

- After Sales Service and Preventive Management

Research & Development

Research is an important part of the wide number of activities performed by us. We have a team of researchers that keeps conducting constant research work which is then used to develop the best product line including Continuous Casting Machine, Sampling and Temperature Manipulators, Vacuum Oxygen Refining Furnace, etc.

Infrastructural Facilities

In our company, we are backed by an outstanding infrastructure facility that contains a modern production facility. It is fitted with technically advanced machinery like Lathe Machine, Grinding Machine, Pipe Cutting Machine, Coiler, Gas Cutting Machine, Bending Machine, etc., a highly sophisticated design wing, R&D facilities and other necessary equipment to maintain seamless and uninterrupted production. Moreover, following is the list of machines included in our facility:

|

Equipment Name |

Qty |

|

Lifting capacity: 50 Tons |

1 No. |

|

Lathe Machine |

1 No. |

|

Grinding Machine |

1 No. |

|

|

|

|

Pipe Cutting Machine |

2 Nos. |

|

|

|

|

Coiler |

2 Nos. |

|

C.R Strip De-coiler |

2 Nos. |

|

Welding Transformer 400Amps Machine |

2 Nos. |

|

Bending Machine |

1No. |

|

Gas Cutting Machine |

4 Sets |

|

Pug Machine Esab |

2 Nos. |

|

Synergic Mig, Mag Welding Machine 600Amps Esab |

1 No. |

|

Welding Rectifier 600 Amps Esab |

4 Nos. |

|

Welding Rectifier 800 Amps Sunshine |

2 Nos. |

|

SAW Welding Machine 1200Amps Esab |

2 Nos. |

|

Bosch Heavy-Duty Angle Grinders AG-9 |

2 Nos. |

|

Electrode Baking Oven |

2 No. |

|

Flux Baking Oven |

1 No. |

|

Bosch Heavy-Duty Angle Grinders AG-7 |

4 Nos. |

|

Bosch Heavy-Duty Angle Grinders AG-4 |

4 Nos. |

|

Circular Gas cutter |

1 Set |

|

|

|

|

|

|

|

D.G. Set 125 KVA |

1 Set |

|

Power Factor Contr. (Capacitor Panel) |

1 Set |

Our vision is to ensure customer loyalty by meeting requirements and gaining everlasting praise & gratitude of clients. We strive to accomplish our vision through the following mission:

- To develop goods that are secure, durable and of finest quality

- To conduct ethical business practices with all the customers

- To care for the environment

- To maintain the most nominal pricing in all our goods including Vacuum Oxygen Refining Furnace, Continuous Casting Machine, Sampling and Temperature Manipulators, etc.

Safety Aspects

The protection, wellness and welfare of all those who work with us and use our goods is considered vital to the sustainability of our company. For which, we ensure there are no accidents in the premises and we successfully present eco-friendly products and services to the customers.