Tundish Spraying Machine

Price 500000 INR/ Set

Tundish Spraying Machine Specification

- Model No

- TSM-2200

- Automation Grade

- Automatic

- Usage & Applications

- For spraying refractory materials inside steel tundishes

- Speed

- Adjustable, Up to 1200 mm/min

- Installation Guideline

- On-site installation & commissioning by qualified technician

- Production Capacity

- 600 Tundish/day

- Accessories

- Spray Nozzles, Hose Pipes, Control Panel

- Driven Type

- Electric Motor Driven

- Temperature Range

- Ambient to 250C

- Efficiency (%)

- >95%

- Frequency

- 50 Hz

- Motor Power

- 2 HP

- Type

- Tundish Spraying Machine

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Voltage

- 415V

- Power

- 5 kW

- Weight (kg)

- Approx. 950 kg

- Dimension (L*W*H)

- 2200 mm x 900 mm x 1600 mm

- Color

- Industrial Grey

- Capacity

- 25 Tundish/hour

- Features

- Uniform spraying, high precision, easy operation, robust construction

- Surface Finish

- Powder Coated

- Power Consumption

- 5.2 kWh

- Machine Type

- Semi-Automatic Spraying Machine

- Operator Panel

- Touchscreen HMI

- Operating Language

- Multi-language interface

- Chassis

- Heavy Duty Industrial Frame

- Spray Radius

- 500-700 mm adjustable

- Nozzle Type

- High Pressure Ceramic Nozzle

- Input Air Pressure

- 6-8 Bar

- Hopper Capacity

- 80 Liters

- Safety Features

- Emergency stop, Overload protection

- Service Support

- On-site and remote technical support

- Mobility

- Mounted on Lockable Wheels

- Noise Level

- <75 dB

- Maintenance Requirement

- Low, simple parts replacement

- Spray Material Compatibility

- Suitable for water-based and solvent-based refractory sprays

- Ambient Working Temperature

- 5°C to 50°C

Tundish Spraying Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 1 Months

About Tundish Spraying Machine

Precision and Efficiency in Tundish Spraying

Designed for large-scale steel foundries, the Tundish Spraying Machine ensures rapid and uniform refractory coating inside tundishes. Its computerized, automatic grade with PLC control delivers high precision with adjustable speed and spray radius, optimizing the refractory application process for improved steel quality and process consistency.

Robust Design and User-Friendly Operation

Constructed from powder-coated mild steel and finished in industrial grey, the TSM-2200 combines durability with ergonomic ease. The lockable wheel chassis and touchscreen HMI simplify maneuvering and operation, while emergency stop and overload protection bolster onsite safety during use.

Versatile Compatibility and Service Support

Whether using water-based or solvent-based refractory materials, the spraying machine adapts effortlessly. It accommodates a wide range of working environments thanks to its 5C50C ambient temperature range and multi-language operator panel. Users benefit from both on-site and remote technical support for uninterrupted operations.

FAQs of Tundish Spraying Machine:

Q: How does the Tundish Spraying Machine achieve uniform application of refractory materials?

A: The Tundish Spraying Machine uses a high-pressure ceramic nozzle and PLC-controlled automatic operation to ensure precise, even distribution of refractory spray inside steel tundishes. Adjustable spray radius and speed settings further refine the application for consistent thickness and coverage.Q: What kinds of refractory spray materials are compatible with this machine?

A: This machine is designed to handle both water-based and solvent-based refractory sprays, making it flexible for various tundish lining requirements in steel manufacturing environments.Q: Where can the Tundish Spraying Machine be used and installed?

A: It is suitable for use inside steel foundries, especially near tundish areas. Installation and commissioning are performed onsite by qualified technicians to ensure optimal setup according to the customers requirements.Q: What is the process for routine maintenance and parts replacement?

A: Routine maintenance is straightforward, with low requirements. The modular design enables quick, simple parts replacement, minimizing downtime and ensuring the machine remains operational with minimal intervention.Q: When should I use the emergency stop or overload protection features?

A: The emergency stop and overload protection should be activated immediately if any operational hazards, unauthorized access, or abnormal machine behaviors are detected during spraying, to ensure safety and prevent equipment damage.Q: What are the benefits of using the touchscreen HMI and multi-language interface?

A: The touchscreen HMI provides intuitive controls, simplifying parameter adjustments and operation monitoring. Multi-language support enables comfortable and accurate use by operators from different linguistic backgrounds, reducing errors and training needs.Q: How does the machine enhance production efficiency for steel tundish spraying applications?

A: By automating the refractory spraying process, the machine significantly increases throughputhandling up to 25 tundishes per hourand ensures greater than 95% application efficiency, lowering labor requirements and improving consistency in tundish lining quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

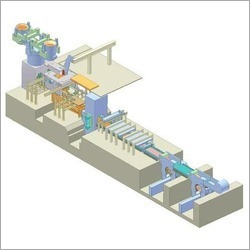

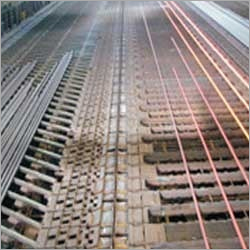

More Products in Continuous Casting Machine Category

Continuous Billet Casting

Price 8500000 INR / Set

Minimum Order Quantity : 1 Set

Model No : CBCM2024

Surface Finish : Other, Smooth, Semibright Billet Finish

Color : Industrial Grey/Blue Finish

Automation Grade : Fully Automatic

Continuous Billet Caster

Price 12200000 INR / Set

Minimum Order Quantity : 1 Set

Model No : CBC320AUTO

Surface Finish : Other, Smooth, ScaledFree Billets

Color : Industrial Grey / Blue

Automation Grade : Fully Automatic

Automatic Rack Type Cooling Bed for CCM

Price 15000000 INR / Set

Minimum Order Quantity : 1 Set

Model No : CBCCMAUTO

Surface Finish : Other, Powder Coated

Color : Industrial Blue & Grey

Automation Grade : Automatic

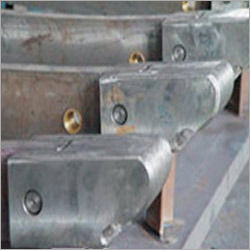

Rigid Dummy Bar Continuous Casting Machine

Price 1000000 INR / Set

Minimum Order Quantity : 1 Set

Model No : RDCCM25

Surface Finish : Polished

Color : Blue / Metallic Grey

Automation Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free