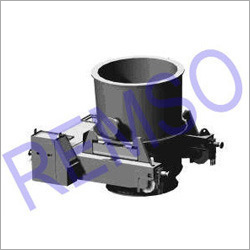

Slab Transfer Car

Price 2500000 INR/ Set

Slab Transfer Car Specification

- Equipment Type

- Slab Transfer Car

- Rotation Type

- Straight or Rotating Option

- Lifting Speed

- 5-15 m/min

- Features

- Automatic Braking, Overload Protection

- Wheel Type

- Steel Wheels with Polyurethane Coating

- Motor Type

- AC Electric Motor

- Control System

- Remote/Manual

- Condition

- New

- Lifting Capacity

- Up to 100 Tons

- Max. Lifting Load

- Up to 100 Tons

- Max. Lifting Height

- Customizable

- Power Source

- Electric

- Power Consumption

- 10-40 kW

- Voltage

- 380V/415V

- Feature

- Corrosion Resistant, Easy Operation

- Attributes

- Heavy Duty, Robust Design

- Material of Construction

- Mild Steel / Alloy Steel

- Paint Finish

- Industrial Grade, Heat Resistant

- Brake Type

- Electromagnetic or Hydraulic

- Platform Size

- Customized as per requirement

- Application

- Steel Mill, Foundry, Rolling Mills

- Safety Features

- Limit Switches, Bumpers, Emergency Stop

- Customization

- Available as per project needs

- Rail Gauge

- Custom (commonly 1435 mm Standard Gauge)

- Running Speed

- Up to 40 m/min

- Operating Temperature

- -10°C to +60°C

- Noise Level

- Low (<75dB)

Slab Transfer Car Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 1 Months

About Slab Transfer Car

The Ladle car is transporting tool for SLABS. The car will carry the CAR filled with SLAB. SLAB TRANSFER CARS serves to transfer the Ladle from the EAF / LRF / VD to the casting position

It consists of Body Frame having tilting arrangement with driving equipment. The SLAB Transfer Car is equipped with a lifting device.

Product details

| Feature | Highly Durable |

| Capacity | 2 - 60 Ton |

| Brand | Remso |

| Model | Remso |

| Material | MS |

A centering device serves to center the trumpet. Weighing is performed by means of load cells. Utilities are supplied by means of power track.

Custom Builds for Diverse Industrial Applications

Every Slab Transfer Car is tailored to fit your sites unique needs, supporting custom platform sizes, rail gauges, lifting heights, and load capacities up to 100 tons. This flexibility ensures seamless integration into your steel mill, foundry, or rolling mill, regardless of your operational scale or layout.

Robust Engineering and Safety Features

Manufactured from high-quality mild or alloy steel, the car features a heat-resistant, industrial-grade paint finish. Built-in safety enhancements, including limit switches, bumpers, emergency stop, automatic braking, and overload protection mechanisms, ensure operator safety and equipment longevity in rigorous environments.

Efficient and Quiet Performance

Operating on advanced AC electric motors and powered by 380V/415V supply, the transfer car maintains low noise levels (<75dB) and optimizes energy use (1040 kW). Its steel wheels with PU coating enable smooth, reliable travel, while variable options for straight or rotating movement enhance maneuverability.

FAQs of Slab Transfer Car:

Q: How is the Slab Transfer Car customized to fit my facilitys specific requirements?

A: The Slab Transfer Car can be engineered to match your exact platform size, rail gauge requirements (with 1435 mm standard or custom options), and lifting heights. Our team works with you to configure features like speed, capacity, control systems, and more, ensuring seamless integration into your workflow.Q: What safety mechanisms are incorporated into this equipment?

A: This car is equipped with limit switches, bumpers, emergency stop controls, automatic braking, and overload protection. These features minimize operational risks, ensuring safe transport of heavy slabs in demanding industrial environments.Q: When should I consider using a slab transfer car in my operation?

A: You should opt for a slab transfer car when safely transporting heavy or hot slabs between production areas, especially where overhead cranes are impractical. It is ideal for steel mills, foundries, and rolling mills seeking efficient, labor-saving slab movement.Q: Where can this equipment be used effectively?

A: This slab transfer car is designed for industrial sites such as steel mills, metal foundries, and rolling mills, but it can be adapted for any facility requiring heavy-duty, robust, and precise slab transport along custom rail systems.Q: What is the process for installing and operating the transfer car?

A: After customizing and manufacturing to your project specifications, installation is completed at your site by our technicians or your in-house team. Operation is straightforward with manual or remote controls, detailed guidance, and easy maintenance protocols provided by our support team.Q: How does the equipment benefit my production process?

A: Automating slab movement enhances operational safety, reduces manual labor, and streamlines workflow. Its heavy-duty, corrosion-resistant design and heat resistance ensure long service life, while precise control systems improve productivity and minimize downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Metal Transferring Equipment Category

Hot Metal Handling Equipment

Price 2200000 INR / Set

Minimum Order Quantity : 1 Set

Attributes : Other, Heavy Duty, Robust Construction

Condition : New

Max. Lifting Load : 50 Ton

Caster Sequence Car

Price 1690000 INR / Set

Minimum Order Quantity : 1 Set

Attributes : Other, Heavy Duty, CorrosionResistant

Condition : New

Max. Lifting Load : 1500 kg

Hot Metal Ladle Transfer Car

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Attributes : Other, Heavyduty construction designed for hightemperature metal handling

Condition : New

Warranty : Provided by the manufacturer usually 1 year or customized terms

Max. Lifting Load : Dependent on customer specifications (e.g. 50 tons 100 tons etc.)

Ladle Transfer Car

Price 1350000 INR / Unit

Minimum Order Quantity : 1 Unit

Attributes : Strong Durable Easy To Operate Rust Proof, Other

Condition : New

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free