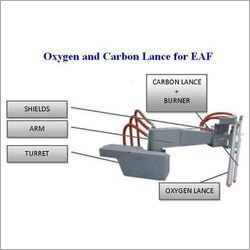

Oxygen & Carbon Lance for EAF

Price 1600000 INR/ Set

Oxygen & Carbon Lance for EAF Specification

- Rating

- High performance

- Feature

- Corrosion-resistant, high thermal stability, precision flow control

- Condition

- New

- Type

- Oxygen & Carbon Lance

- Usage

- For Electric Arc Furnace (EAF) operation

- Power

- Manual/Mechanical operation, no power required

- Size

- Customizable as per EAF requirements

- Dimensions

- Available in various lengths and diameters

- Weight

- Varies depending on length and diameter

- Application

- Steelmaking, metal melting, EAF processes

- Fuel Type

- Oxygen and Carbon consumption

- Capacity

- Supports high-capacity furnaces

- Lance End Design

- Single or multi-hole injection

- Surface Finish

- Smooth, burr-free exterior

- Temperature Resistance

- Up to 1700°C

- Coating

- Anti-oxidation or anti-corrosive coating options

- Compliance

- Meets industrial safety standards and quality assurance

- Service Life

- Optimized for extended furnace campaigns

- Material

- High quality mild steel/SS

- Connector Type

- Standard threaded/bayonet connection

- Customization

- Available as per specific furnace and process requirements

Oxygen & Carbon Lance for EAF Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1 Set Per Month

- Delivery Time

- 15 Days

About Oxygen & Carbon Lance for EAF

Oxygen and Carbon Lance for Electric Arc Furnace

Other Information

Superior Construction and Thermal Stability

These oxygen and carbon lances are crafted from premium mild steel or stainless steel, featuring specialized coatings for anti-oxidation and anti-corrosive protection. The smooth, burr-free finish and precise manufacturing ensure safe handling and reliable performance under extreme temperatures, up to 1700C. Their robust construction supports extended service life, making them the preferred choice for demanding electric arc furnace applications.

Precision Flow Control for EAF Processes

Our lances feature single or multi-hole injection end designs for tailored gas delivery during EAF operations. This allows for controlled, targeted injection of oxygen or carbon, optimizing the melting and refining process while reducing energy and material wastage. The standard threaded or bayonet connectors ensure secure installation and compatibility with most furnace setups.

Versatile Customization for Specific Needs

Recognizing the diverse requirements of the steelmaking industry, we offer customization in lance length, diameter, end design, and coating. Each lance can be adapted to specific furnace sizes and process requirements, ensuring ideal compatibility and peak operational performance. Our products comply with rigorous industrial safety and quality standards for total peace of mind.

FAQs of Oxygen & Carbon Lance for EAF:

Q: How does an oxygen or carbon lance function in an Electric Arc Furnace (EAF)?

A: An oxygen or carbon lance introduces oxygen and/or carbon into the molten bath or furnace atmosphere, enhancing metal melting, decarburization, slag foaming, and refining processes. This results in improved reaction rates and cleaner steel production.Q: What are the available customization options for these lances?

A: Customization is available for lance length, diameter, connector type (threaded or bayonet), end design (single or multi-hole), and anti-corrosive coatings. We tailor each lance to your EAFs specific size and operational requirements.Q: When should I replace or inspect my oxygen/carbon lance?

A: Lances should be inspected regularly for signs of wear, corrosion, or blockage, especially after each furnace campaign. Replacement is recommended when there is significant deterioration or diminished performance, ensuring safety and process efficiency.Q: Where are these lances commonly used?

A: Our oxygen and carbon lances are widely used in steelmaking, metal melting, and refining operations in Electric Arc Furnaces (EAF) found in steel plants, foundries, and metal recycling facilities across India and abroad.Q: What benefits does the anti-corrosive coating provide?

A: The anti-corrosive or anti-oxidation coating protects the lance from aggressive furnace environments, extending service life, maintaining structural integrity, and ensuring reliable performance even at temperatures up to 1700C.Q: How does the precision flow control feature contribute to EAF efficiency?

A: Precision flow control, provided by the single or multi-hole injection end design, enables accurate delivery of gases. This reduces material wastage, optimizes thermal and chemical reactions, and results in higher quality steel output.Q: What makes these lances compliant with industrial safety standards?

A: Each lance is manufactured to meet strict industrial quality and safety requirements, featuring high-grade materials, secure connections, and smooth, burr-free surfaces that help prevent operational hazards and ensure user safety during handling and use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

Carbon Injector System For Electric Arc Furnace

Price 3500000 INR / Set

Minimum Order Quantity : 1 Set

Feature : High output efficiency, Easy installation, Autocontrolled dosage

Condition : New

Usage : Other, For Electric Arc Furnaces

Type : Automatic Carbon Injection System

Bottom Shell for Electric Arc Furnace

Price 3000000 INR / Set

Minimum Order Quantity : 1 Set

Feature : High Strength, Corrosion Resistant, Heat Resistant, Durable Construction

Condition : New

Usage : Other, Electric Arc Furnace

Type : Bottom Shell

Carbon Injection Dispenser

Price 2100000 INR / Set

Minimum Order Quantity : 1 Set

Feature : Corrosion Resistant, High Precision Dosing, Digital Control Panel

Condition : New

Usage : Other, Industrial Carbon Injection

Type : Automatic Dispenser

Oxygen & Carbon Lance Manipulator

Price 3200000 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : Long Service Life

Condition : New

Usage : Other

Type : Oxygen & Carbon Lance Manipulator

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS