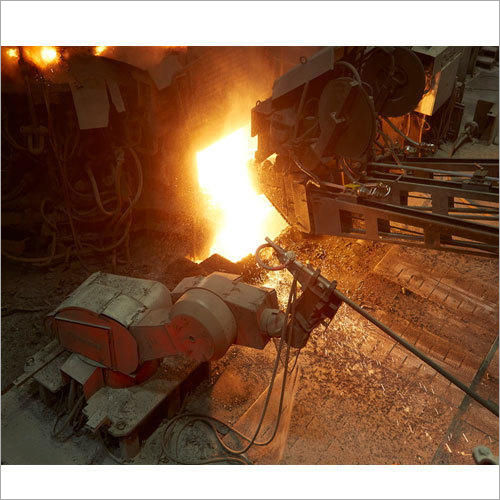

Bottom Shell for Electric Arc Furnace

Price 3000000 INR/ Set

Bottom Shell for Electric Arc Furnace Specification

- Feature

- High Strength, Corrosion Resistant, Heat Resistant, Durable Construction

- Rating

- Heavy Duty

- Condition

- New

- Type

- Bottom Shell

- Usage

- Electric Arc Furnace

- Power

- Depends on Furnace Capacity

- Voltage

- Suitable for EAF specification

- Size

- Customized as per requirement

- Dimensions

- As per drawing or specification

- Weight

- As per design and size

- Application

- Steel Melting Shop, Electric Arc Furnace

- Fuel Type

- Electric

- Capacity

- Up to 200 Tons

- Structure

- Ribbed/Bolted design for high load capacity

- Manufacturing Lead Time

- 4 to 8 weeks depending on order volume

- Packaging

- Heavy duty export worthy wooden box or as specified by customer

- Insulation

- With or without refractory lining

- Service Life

- Extended service life under standard operating conditions

- Production Technique

- CO2 welding, robotic welding, advanced machining

- Custom Availability

- Can be fabricated according to drawing or specification

- Surface Treatment

- Anti-corrosion paint or customized as per user demand

- Material

- Premium carbon steel with copper cooling inserts as required

- Testing

- Ultrasonic and X-ray tested welds for quality assurance

- Finishing

- Machined and precision finished

- Compatibility

- Compatible with major EAF brands and models

- Heat Resistance

- Designed for high temperature thermal shock resistance

Bottom Shell for Electric Arc Furnace Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 1 Set Per Month

- Delivery Time

- 15 Days

About Bottom Shell for Electric Arc Furnace

Versatile Industrial Applications of EAF Bottom Shell

The Bottom Shell for Electric Arc Furnace, beyond its primary use in steel melting shops, finds commercial applicability in smelting plants, foundries, and high-temperature processing units. Suitable for application with varied media like steel scrap, alloys, and other metal charges, it enhances operational efficiency in recycling, forging, and specialized metal production environments. Its robust and corrosion-resistant design underscores dependable performance for both small-scale operations and large, industrial steel plants.

Reliable Payment, Supply, and Packaging Solutions

Order completion is streamlined with flexible payment options and a transparent list price system. Our supply ability adapts to both single custom units and bulk volume orders, ensuring quick dispatch within a 48 week manufacturing window. Each bottom shell is packaged in a heavy-duty export-worthy wooden box or as per customers request for optimal safety. This thoughtful packaging approach supports global export logistics with uncompromised product integrity during transit.

FAQs of Bottom Shell for Electric Arc Furnace:

Q: How is the bottom shell for electric arc furnaces manufactured?

A: The bottom shell is manufactured using premium carbon steel and copper cooling inserts, CO2 and robotic welding, and advanced machining techniques. Each unit undergoes ultrasonic and X-ray inspection for weld quality assurance to ensure reliability and strength.Q: What benefits does the bottom shell offer for EAF operations?

A: It delivers high thermal shock resistance, extended service life, and robust support for heavy-duty steel melting applications. The precision finishing, anti-corrosion treatment, and compatibility with major EAF brands further optimize operational efficiency and reduce downtime.Q: When can customers expect completion and shipment of their order?

A: Manufacturing lead time ranges from 4 to 8 weeks, depending on order volume and customization requirements. Quick dispatch is assured after order completion, and clients receive regular updates throughout the production process.Q: Where can this bottom shell be used commercially?

A: It is designed for use in steel melting shops, smelting units, foundries, and any high-temperature industrial facility requiring durable and corrosion-resistant EAF shells.Q: What customization options are available for this product?

A: We offer customized sizing, finishing, insulation options, and surface treatments per user drawings or specifications. Packaging can also be tailored to meet unique shipping and handling needs.Q: How does the product ensure long service life and heat resistance?

A: Constructed from high-strength materials and designed for superior heat resistance, the bottom shell features additional options like refractory linings and advanced surface treatments, ensuring durability under the harshest operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

Furnace Gantry for Electric Arc Furnace

Price 3500000 INR / Set

Minimum Order Quantity : 1 Set

Feature : Robust construction, Corrosion resistant, Smooth operation

Usage : Other, Electric Arc Furnace (EAF) Operations

Type : Furnace Gantry

Condition : New

Water Cooled Furnace Roof

Price 1600000 INR / Set

Minimum Order Quantity : 1 Set

Feature : Corrosion resistant tubes, efficient heat dissipation, robust structure

Usage : Other, Cover and protect furnace interior, heat insulation

Type : Water Cooled Furnace Roof

Condition : New

Temperature Measuring Lance For Electric Arc Furnace

Price 4500000 INR / Set

Minimum Order Quantity : 1 , , Set

Feature : Robust construction, high accuracy, replaceable probes

Usage : Other, For Electric Arc Furnace

Type : Temperature Measuring Lance

Condition : New

Tubular Panel For Eaf

Price 1800000 INR / Set

Minimum Order Quantity : 1 Set

Feature : Long Service Life

Usage : Other

Type : Tubular Panel for EAF

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free