Carbon Injection Dispenser

Price 2100000 INR/ Set

Carbon Injection Dispenser Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 10 Sets Per Day

- Delivery Time

- 3 Days

About Carbon Injection Dispenser

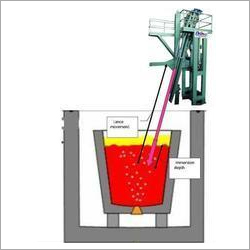

I am offering a carbon injection system that has been designed to meet the demanding requirements of the EAF process for the improvement of metallurgical process. The system uses closed loop control with real-time carbon flow rate feedback to provide the exact carbon flowrate that is requested at any time. The use of dispenser, with precise flow-rate control for each injector, allows an efficient injection of carbon fines generates chemical energy by the combustion of C to CO in the liquid bath, and retain it in the slag/steel.The foamed slag that transfers and distributes the chemical energy generated over the entire liquid steel surface. The capacity of the carbon injection system shall be able to sustain with the flow rates and quantities requirements of one carbon lance during at least an entire heat. Consequently we propose the supply of dispensers with 1500 liters capacity. The powder fines could be stored into storage silos. The dispenser should be installed as close as possible to the EAF, in the event that is not feasible, and it is necessary to move away from the furnace area, the maximum linear distance should not exceed 80 meters.

The process of filling the powder fines is automatically controlled by pneumatic on /off fail safe valves and level limit switch.The fines enter to the conveying pipeline, from the dispenser lower exits and transfer the mixture of fines and compressed air to the carbon lance.

Product details

| Usage | Steel Industry |

| Installation Service | Yes |

| Design Type | Customized |

| Injectable Form | Solution |

| Grade Standard | Industrial |

| Material | Cast Iron |

Our Carbon Injector Systems runs trouble free operation with good quality and proper sizing of the powder fines. The equipments shall be equipped with Moisture removing system of the fine to remove the moist from the air that cause problem in maintenance with solenoids and valves and clogging of injection lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electric Arc Furnace Category

Lance Manipulator Revolving Turret for EAF

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Lance Manipulator Revolving Turret for EAF

Condition : New

Feature : Long Service Life

Size : Different Size Available

Door Lance Manipulator for Electric Arc Furnace

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Electric Arc Furnace

Condition : New

Feature : Long Service Life

Size : Different Size Available

Carbon Injector System For Electric Arc Furnace

Price 3500000 INR / Set

Minimum Order Quantity : 1 Set

Send Inquiry

Send Inquiry