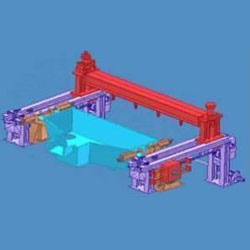

Tundish Turnover Device

Price 1500000 INR/ Set

Tundish Turnover Device Specification

- Shape

- Rectangular base with adjustable arms

- Phase

- Three Phase

- Torque

- Up to 10000 Nm

- Diameter

- N/A (not applicable to turnover device design)

- Product Type

- Tundish Turnover Device

- General Use

- Continuous casting, metallurgical industry

- Material

- Structural Steel

- Type

- Mechanical lifting & turnover type

- Capacity

- Customizable as per requirements

- Weight (kg)

- 5000-9500 kg (varies with model)

- Computerized

- No

- Automatic

- Yes

- Touch Screen

- No

- Control System

- Electric or Hydraulic

- Surface Treatment

- Painted/Anti-corrosive coating

- QC System

- ISO 9001:2015 certified

- Tolerance

- 1 mm

- Drawing

- Available

- Voltage

- 380V/415V, 3 Phase

- Dimension (L*W*H)

- As per specification/model

- Feature

- High stability, easy operation, robust construction

- Color

- Standard industrial grey or as required

- Service Life

- Min. 10 years under normal working conditions

- Spare Parts Availability

- Readily available from manufacturer

- Operation Method

- Remote controlled or manual

- Lifting Speed

- Up to 250 mm/min (customizable)

- Safety Features

- Limit switches, emergency stop, overload protection

- Noise Level

- Less than 75 dB

- Power Source

- Electric/Hydraulic

- Maintenance

- Low, routine check recommended

- Turnover Angle

- 0-90° adjustable

- Application

- Used for safe and efficient tundish positioning and replacement

- Lubrication

- Centralized automatic lubrication system

- Environment

- Designed for high temperature and harsh foundry floors

- Oil Cylinder Quantity

- 2 or more, depending on capacity

- Installation

- Floor mounted, supplied with foundation bolts

Tundish Turnover Device Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 20 Sets Per Month

- Delivery Time

- 1 Months

About Tundish Turnover Device

While keeping in mind the requirements of our valuable customers, we are offering a distinguished range of Tundish Turnover Device. The offered products are designed using supreme quality of basic materials and up to date technology in compliance with industrial standards. Our distinguished customers can avail this range at market leading prices.

Features:

- Simple design

- Functional efficiency

- Resistance against corrosion

Product details

| Application | Industrial |

| Machine Body Material | MS |

| Material | Cast Iron |

| Design Type | Standard |

| Brand | Remso |

| Country of Origin | Made in India |

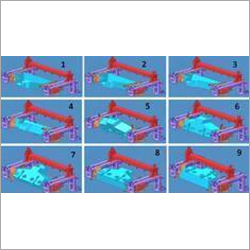

Precision Positioning for Casting Operations

The Tundish Turnover Device offers highly accurate tundish manipulation, supporting continuous casting processes. Adjustable arms and precise motion control ensure safe, systematic replacement and positioning, even in harsh foundry environments. With advanced safety features and a robust structural steel build, this system is geared for both efficiency and operator protection.

Customizable and Durable Solution

Built from high-quality structural steel and coated with anti-corrosive paint, the device withstands high temperatures and industrial wear. Multiple models with varying capacities, turnover angles, and dimensions are available to meet unique operational needs. The centralized lubrication system and readily available spare parts further enhance its durability and ease of maintenance.

FAQs of Tundish Turnover Device:

Q: How is the Tundish Turnover Device operated?

A: The device can be operated remotely or manually, offering flexibility to suit your workflow. Its electric or hydraulic control system allows for precise adjustments of the turnover angle from 0 to 90.Q: What safety features are included with this turnover device?

A: The system is equipped with limit switches, an emergency stop, and overload protection to ensure safe operation, especially in demanding metallurgical environments.Q: When and where should the Tundish Turnover Device be installed?

A: It should be floor-mounted in steel plants and metallurgical facilities that carry out continuous casting. Installation is straightforward with the supplied foundation bolts, and the device is designed for high-temperature, harsh foundry conditions.Q: What is the process for replacing a tundish using this device?

A: Simply position the tundish onto the device, secure it, and use the remote or manual controls to adjust the turnover angle as required for removal or replacement, benefiting from centralized lubrication and stable operation.Q: What are the usage benefits of this device over manual handling?

A: Using this device reduces manual labor risks, increases operational efficiency, and maintains consistent positioning accuracy, improving safety and productivity on the foundry floor.Q: Is routine maintenance required for the Tundish Turnover Device?

A: Routine checks are recommended, but maintenance needs are minimal due to the centralized automatic lubrication system. Spare parts are readily available from the manufacturer, ensuring long-term reliability.Q: What are the power and customization options available?

A: The device can be powered by electrical or hydraulic systems and is compatible with 380V/415V, 3-phase power. Capacity, dimensions, and other specifications can be customized as per your operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tundish Tilter Turnover Device Category

Tundish Tilter for Bloom Caster

Price 525000 INR / Set

Minimum Order Quantity : 1 Set

Type : Other, Electrohydraulic tilter

General Use : Tilting and positioning tundish in continuous casting bloom machines

Drawing : Other, Available upon request

Voltage : 415 V AC, 3 Phase

Tundish Tilter Turnover Device

Price 1600000 INR / Set

Minimum Order Quantity : 1 Set

Type : Other, Hydraulic or Mechanical Tilter

General Use : Steel Casting and Metallurgy Applications

Drawing : Other, Available on Request

Voltage : 415V, 3 Phase

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS