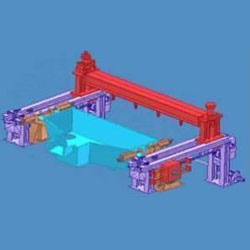

Tundish Tilter for Bloom Caster

Price 525000 INR/ Set

Tundish Tilter for Bloom Caster Specification

- Shape

- Rectangular base with tilting cradle

- Torque

- Rated up to 12000 Nm

- Diameter

- Suitable for tundish width up to 1800 mm

- Phase

- Three Phase

- Product Type

- Tundish Tilter for Bloom Caster

- General Use

- Tilting and positioning tundish in continuous casting bloom machines

- Material

- Heavy-duty structural steel

- Type

- Electro-hydraulic tilter

- Capacity

- Typically up to 20 tons (varies as per design)

- Weight (kg)

- Approx. 3500 kg (depending on size & model)

- Computerized

- Yes

- Automatic

- Yes

- Touch Screen

- Optional (available on request)

- Control System

- PLC based automated control

- Surface Treatment

- Paint coated / Anti-corrosive coating

- QC System

- Comprehensive in-house QC before dispatch

- Tolerance

- 1 mm

- Drawing

- Available upon request

- Voltage

- 415 V AC, 3 Phase

- Dimension (L*W*H)

- Approx. 4200 x 1850 x 1700 mm

- Feature

- Smooth tilting motion, high load-bearing, error-free operation, durable build

- Color

- Industrial safety yellow/blue (customizable)

- Installation

- On-site commissioning and training provided

- Maintenance

- Low maintenance, easy-access service points

- Operation Method

- Remote push-button or centralized control desk

- Certificates

- ISO 9001:2015 certified manufacturing

- Hydraulic System

- High pressure, leak-proof design with overload protection

- Power Consumption

- Approx. 7.5 kW (depends on load)

- Safety Features

- Interlock system, overload relays, mechanical stoppers, emergency stop switch

- Noise Level

- <75 dB during operation

- Working Temperature

- Suitable for >50°C ambient environments

- Application

- Steel melting shop, continuous casting plant

Tundish Tilter for Bloom Caster Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 20 Sets Per Month

- Delivery Time

- 1 Months

About Tundish Tilter for Bloom Caster

Pioneers in this industry, we are offering a wonderful range of Tundish Tilter for Bloom Caster. These industrial sector machines are manufactured using fine grade raw material & latest technology under the guidance of our skilled professionals. Apart from this, to meet the demands of our customers, we also offer this range in several other technical specifications given by our customers.

Features:

- Hassle free performance

- High speed

- Easy to operate

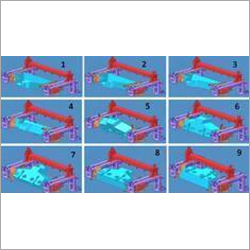

Advanced Tilting Technology

Equipped with a high-pressure electro-hydraulic system, this tundish tilter ensures stable and precise movements, making it ideal for modern bloom casting requirements. Its overload protection and seamless control options guarantee operational safety and continuity in demanding steel plant environments.

User-Centric Operation & Control

Operators can control the tilter either through a remote push-button or from a centralized control desk, with an optional touch screen interface. The intuitive PLC-based automation significantly reduces operator intervention and maintains consistent, reliable performance under varied load conditions.

Designed for Safety & Reliability

Multilayered safety features, such as interlock systems, overload relays, mechanical stoppers, and a prominent emergency stop switch, ensure both personnel and equipment safety. The machines robust anti-corrosive coating and in-house quality controls uphold long-term durability and error-free operation.

FAQs of Tundish Tilter for Bloom Caster:

Q: How is the tundish tilter for bloom caster operated?

A: The tundish tilter can be operated via a remote push-button or from a centralized control desk. An optional touch screen panel is also available upon request, offering flexibility in control methods depending on plant requirements.Q: What safety features are integrated into this hydraulic tundish tilter?

A: This model is equipped with interlock systems, overload relays, mechanical stoppers, and an emergency stop switch. These features collectively protect both personnel and machinery, ensuring safe operation at all times.Q: When should maintenance be performed on the tundish tilter?

A: Routine inspections should follow your plants standard maintenance schedule. However, thanks to its low-maintenance design and easy-access service points, regular visual checks and scheduled lubrication will usually suffice to maintain optimal performance.Q: Where is the tundish tilter installed and commissioned?

A: Installation, commissioning, and operator training are performed directly on-site at the customers facility. Our technical team ensures optimal integration and operational readiness within your steel melting or casting plant.Q: What is the process of tilting and positioning the tundish?

A: The process involves PLC-controlled hydraulic tilting, activated via control console or remote buttons. The system delivers precise motion, smooth operation, and accurate tundish positioning, all with built-in overload and safety protections.Q: How does using this tundish tilter benefit my steel plant operations?

A: Using this tilter ensures safe, error-free, and efficient tundish positioning in bloom casting machines. Its durable design, high load capacity, and automated features minimize downtime, enhance productivity, and reduce operator risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tundish Tilter Turnover Device Category

Tundish Turnover Device

Price 1500000 INR / Set

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : As per specification/model

Color : Standard industrial grey or as required

Feature : Other, High stability, easy operation, robust construction

Voltage : 380V/415V, 3 Phase

Tundish Tilter Turnover Device

Price 1600000 INR / Set

Minimum Order Quantity : 1 Set

Dimension (L*W*H) : 3800 x 1800 x 2100 mm (Typical)

Color : Industrial Grey / Customizable

Feature : Other, Robust Construction, Smooth Tilting, High Precision

Voltage : 415V, 3 Phase

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS