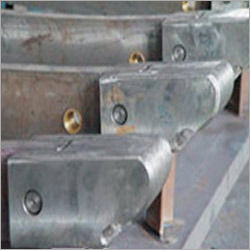

Kiln Shell & Silo

Price 4500000 INR/ Set

Kiln Shell & Silo Specification

- Driven Type

- Electric

- Speed

- Variable as per requirement

- Frequency

- 50 Hz

- Usage & Applications

- Cement, Chemical, Mining, Mineral Processing Plants

- Installation Guideline

- Site supervision & support provided

- Model No

- KS Series

- Automation Grade

- Semi-Automatic

- Efficiency (%)

- Up to 98%

- Motor Power

- As per design

- Temperature Range

- Up to 1450C

- Accessories

- Manhole, Sampling Port, Level Indicators, Hoppers

- Production Capacity

- As per application

- Type

- Kiln Shell & Silo

- Material

- Mild Steel / Alloy Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Based

- Drive Type

- Gear Motor Drive

- Voltage

- 380 - 440 V

- Power

- As per model

- Weight (kg)

- Custom/As per design

- Dimension (L*W*H)

- As per customer requirements

- Color

- Grey / Custom

- Capacity

- Up to 1000 TPD (Ton Per Day)

- Features

- High strength, Durable, Corrosion resistant, Precision engineered

- Surface Finish

- Anti-corrosive coating

- Power Consumption

- Low/Optimized

- Machine Type

- Rotary Kiln Shell and Vertical Storage Silo

- Mounting Type

- Base Mounted / Skid Mounted

- Welding Type

- Submerged Arc/Manual Arc

- Inspection Openings

- Provided as per standard

- Seismic Design

- Available as per site requirements

- Custom Engineering

- Available upon request

- Cylinder Shape

- Horizontal (kiln), Vertical (silo)

- Operation Mode

- Continuous

- Shell Thickness

- 20 mm to 60 mm (customizable)

- Painting

- Epoxy/Enamel

- Heat Treatment

- Stress relieved

- Insulation

- Available on request

- Silo Volume

- 50 m³ to 1000 m³

Kiln Shell & Silo Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 1 Months

About Kiln Shell & Silo

Remso manufacture 100 TPD, 300 TPD, 500 TPD plants and others for the sponge iron industry sector. Kiln Shell for Burning Zone, Kiln Shall, Kiln/cooler tyre, Kiln/cooler support roller, Kiln/cooler support roller shaft, Kiln/cooler support roller assembly with bearing housing, Kiln/cooler, Support Roller, Kiln Guide Roller, Cooler Supporting Roller as per your specification & drawings.Further, we can also offer these in form of Cement Plant Equipment, Mining Industry Equipment, Sugar Mill Equipment.

Product details

| Material | GI |

| Max Temperature | 2000-2500 |

| Material Loading Capacity | 3000-5000 kg |

Precision Engineered for Demanding Industries

The KS Series Kiln Shells and Silos are constructed for ultimate strength and endurance. With customizable dimensions, shell thickness, and configurable mounting, these units meet rigorous operational challenges in various industrial settings. Our systems deliver consistent resultswhether in high-temperature processes or tough storage environments.

Leading Customization and Safety Features

Designed to meet unique application requirements, each unit offers options like anti-corrosive epoxy finishes, seismic-resistant design, insulation, and access ports. Advanced stress-relief treatments and quality welding guarantee longevity. Our team provides engineering support and supervision for smooth installation and operation.

Efficient and Reliable Operation

Enjoy low power consumption, PLC-based control, variable-speed drives, and a host of accessories for monitoring and maintenance. Whether for continuous rotary kiln processes or bulk silo storage, the KS Series ensures efficiency up to 98%, supporting your productivity and minimizing operational interruptions.

FAQs of Kiln Shell & Silo:

Q: How do you determine the appropriate shell thickness and dimension for a customized kiln shell or silo?

A: Shell thickness (20 mm to 60 mm) and dimensions are specified based on process parameters, storage requirements, and operational loading. Our engineering team collaborates with clients to assess application needs and site conditions before finalizing design specifications.Q: What is the typical process for installing and commissioning KS Series Kiln Shells & Silos?

A: Installation involves base or skid mounting according to site arrangements. We provide complete installation guidelines, on-site supervision, and technical support. Commissioning includes inspection of welding, insulation (if requested), drive system checks, and control system setup to ensure safe, efficient startup.Q: Where are access openings and inspection ports typically located?

A: Inspection openings, manholes, and sampling ports are provided as per industrial standards and customer requirements. Placement ensures convenient access for routine maintenance, sampling, and safety checks, enhancing operational reliability.Q: What are the main benefits of choosing the KS Series for industrial applications?

A: The KS Series offers exceptional durability, high efficiency (up to 98%), precision engineering, and corrosion-resistant finishes. Custom engineering, seismic design, and a wide range of accessories increase flexibility and ensure safe, long-term operation in demanding environments.Q: How is seismic design incorporated into the kiln shell and silo systems?

A: Seismic design is included based on site-specific requirements and relevant safety standards. Structural reinforcements and mounting options are tailored to provide optimal stability and protection against seismic events, ensuring operational safety.Q: When is insulation or stress relief heat treatment recommended for these products?

A: Insulation is suggested for processes involving significant temperature variation or to improve energy efficiency. Stress relief heat treatment is standard to minimize internal stresses from welding, boosting structural integrityparticularly for high-temperature and heavy-duty applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Continuous Casting Machine Category

Rigid Dummy Bar Continuous Casting Machine

Price 1000000 INR / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Color : Blue / Metallic Grey

Usage & Applications : Continuous Steel Casting, Metallurgical Industry

Computerized : Yes

Bloom Caster

Price 1500000 INR / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Color : Grey

Usage & Applications : Steel Bloom Casting in Steel Plants

Computerized : Yes

Tundish for Continuous Casting Machine

Price 600000 INR / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Other, Manual / SemiAutomatic

Color : Industrial Blue / Grey

Usage & Applications : Intermediate receptacle for molten steel between ladle and mould in CCM

Computerized : No

Billet Continuous Casting Machine

Price 12000000 INR / Set

Minimum Order Quantity : 1 Set

Automatic Grade : Automatic

Color : Industrial Standard (typically metallic grey/blue)

Usage & Applications : Steel billet production, continuous casting process for foundries and steel plants

Computerized : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS